Some things to consider before making these are that there is a clearance problem on the 1988 on cars with anti lock brakes. Also, to get full benefit from these, the ECU needs to be modified for full throttle enrichment and the acceleration enrichment curve needs to be modified as there is twice as much throttle with the same opening as far as the throttle position sensor sees. For ECU modification information, click HERE. Other modifications are covered as the article goes on.

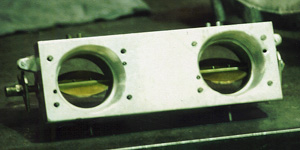

Coming up with the pieces was not a problem so I set out to make a set having no design plan. I wanted to keep the position of the throttle shaft and the air filter plate in the stock plane so as to make it fit in the car. I started out with a 1" x 3" x 11" block of aluminum. This was determined by a straight edge across the face of the manifold to the width of the dual throttles and measuring in at the edge. I decided that if I used a 1" thick block, it would fit in the manifold after machining. I positioned a throttle body in the center and marked the 4 bolt holes. I then used these holes for the center holes of the dual throttles. From there it was just a matter of cutting a 2.5" hole in the center and drilling and tapping the 8 holes for the throttles.

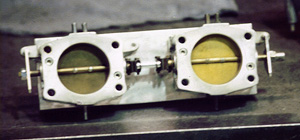

I polished the inside to a bellmouth shape for better air flow. The connecting linkage between the two throttles is off of an older Jaguar dual carb setup. These links are also used on many of the British cars. These allow flex as it is rather difficult to get the throttles in perfect alignment. Rather than carve out an opening for the throttle stops, I positioned them on the outside.

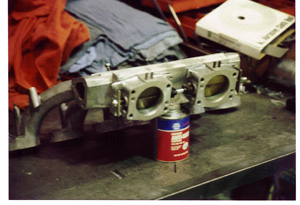

The next step was to machine out the face of the manifold to accept the quad throttle block. This was done on an end mill with the original face of the throttle mount as the start. This made sure that the new throttles would be in the same plane and angle as the original. Before the block was welded in place, I took advantage of the access and smoothed out the individual runner openings as the casting was rather rough. The picture on the left shows the block welded in place.

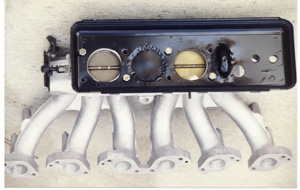

The air filter base was modified next. This involved taking a throttle, bolting it onto two of the holes and marking the openings. Remove and cut them out. The original center hole will need a 2.5" metal plate welded in to fill it. Then repeat for the other opening. There is a depression built into the air filter base for the throttle to turn in. This will need to be cut out and relocated appropriately. A little grinding and smoothing out and it can be made to look very nice.

The picture above is an inside view of the finished product. Note the shorter throttle shaft. The rear plates are turned around to give room to make the throttles. Note that the redundant throttle top openings are plugged off. The only change from this picture is that the front tap on the rear throttle was used for the distributor vacuum as there was a very slight stretch or delay in the throttle when using the front one. The throttle plate also had the rear edge ground slightly so as to give throttle vacuum a little sooner. Another modification was to the auxiliary air valve. With the extra throttles, there was a bit more air than the engine needed to idle and the AIR was at it’s limit adjustment. As it is a valve that moves up and down accordingly to temperature, it was just a matter of pressing the inside control in further to close off some of the air flow. You might have to do this a couple of times as if you go to far, there is not much way to pull it back out. The dipstick had to be bent to come out in a different place. The throttle springs mount on a tab mounted on the cylinder head. It is just a matter of adding a couple and moving the originals as needed for the springs to align properly.

I also enlarged the air filter openings and ducted fresh air from behind the headlights. See the pictures below for the final product.