The Long & Short of Jaguar Racks

by Richard Maury

Over the years there has been a lot of confusion about Jaguar steering racks and their interchangeability. To better understand which racks will interchange, it is first necessary to explain the differences between the various units.

The racks discussed here are the Adwest-manufactured racks that were installed in the Series 2 and 3 XKE, the XJ6 and 12, and the XJS. Along about 1993, Jaguar switched suppliers to the ZF brand of rack. This rack is not better or worse, just different. One of the big differences on the ZF rack is that it is indexed so that the steering wheel is centered. The pinion position differs depending on the model and is not adjustable. The Adwest racks were not indexed and the steering wheel centering was done in the column when installing a new rack.

On the XKE models, the easiest way to tell if the rack is for a V12 or 6 cylinder is to look at the position of the pinion. The V12 has the pinion 90 degrees out from the main body whereas the 6 cylinder pinion is at a slight angle. The XKE range, along with the early XJ6 and 12, used what is referred to now as the "tall tower" rack.

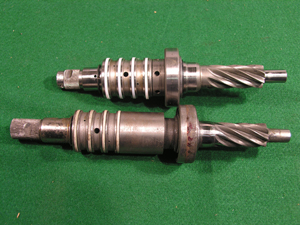

The picture above left shows three pinions. The one on the left is a tall tower XJ6 pinion. The middle one is a 6 cylinder XKE power rack. The one on the far right is a V12. Note that they are all different and are NOT interchangeable.

The picture above right shows a tall pinion versus a short one. The short pinion is a 7 tooth for comparison purposes. The V12 and XJ6 pinions also vary in the seal surface diameter. The above picture also shows the larger seal surface. The smaller seal surfaces do not taper (flare out) and are the same diameter as the gears. This is shown in the picture below left of two pinions from early XJ sedans (tall racks). The larger seal surfaces are used in the later racks.

The picture above right shows a later tall tower rack on the left, a 7 tooth short tower in the middle and a 8 tooth short tower on the right. Note the much larger seal surface on the short tower racks. Also noticeable on the short tower racks is the difference in the size of the gear sets, with the 8 tooth being the larger.

Before we get too involved in the short racks, let's look at the applications of the tall racks. There are basically three versions of the tall rack. The differences are internal and each requires a different seal kit. As an assembly, they are interchangeable, they steer the same, and have the same ratio and assist rate. Some of the internal parts are different so it is important to know what rack you have if you need parts. The tall rack was introduced on the XJ6 in 1968. The early ones used the same rebuild kit as the 6 cylinder XKE rack, though not many of the hard parts are interchangeable. About 1970, a rack with a much-improved internal design was introduced, the improvement mainly being better main shaft seals.

The early racks can be easily identified by a nylon vent line between the sides of the rack. Around 1973, this was changed to a metal vent pipe. This change was also implemented in the V12 XKE. The tall tower rack continued to be used in the XJ6 until the vehicle received fuel injection in 1978. The main reason the rack was changed was due to the installation of a catalytic converter that left insufficient room for the two hoses to go down the side of the rack and enter from the bottom. The change was made at the time of the switch to fuel injection, not catalytic converters, as the earlier 1976-77 carbureted XJ6 car also had a cat but it was located in the middle of the car and didn't interfere with the rack. In late 1974, the XJ12 also received fuel injection and began using the short tower rack. The Series 1 and 1974 carbureted XJ12 used the tall tower rack identical to the 6 cylinder cars at the time.

When Jaguar put the short tower rack into the 12 cylinder in 1974, they used the 8 tooth pinion as in the picture above on the right. The XJS also used this same rack. The XJS never used a long neck rack, as it had fuel injection and catalytic converters from the beginning. The XJ6, on the other hand, used a short tower rack with the 7 tooth pinion from 1978-1982. In 1983 the 7 tooth pinion was dropped and all of the cars used the 8 tooth pinion, whether XJ6, XJ12, or XJS.

A close-up of the two pinions is below right, with the 7 tooth being the smaller one on the left, and the 8 tooth on the right. To change to an 8 tooth pinion on your rack is not as simple as just replacing the pinion. The rack housings are the same so to make room for the larger pinion, the rack teeth were cut deeper. This also made them a bit wider, which can be seen if you hold the two racks side by side. Therefore, if you have a 7 tooth rack and want an 8 tooth rack, the easiest way is to replace the whole rack. Don't think the changes are over yet because they are not!

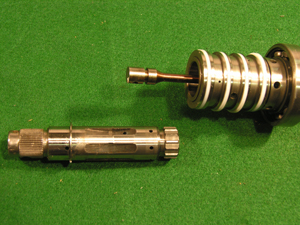

In the picture above left is a pinion head with the internals exposed. The rod coming out of the piece on the right is the torsion bar which controls how much effort it takes to turn the steering wheel before assist starts. The larger the bar, the heavier the steering. All of the tall racks have the same torsion bar so have they all the same steering effort (which is very light by modern standards).

Please note that reducing the power steering pump pressure is NOT the correct way to get firmer steering. Reduced pressure might feel nice under some conditions but could be dangerous if assist is not there when needed. There is a pin that holds these two parts together and it can get loose with age, and the O-ring that goes in the small groove at the end of the torsion bar can become hard. This O-ring is a common leak point and should be replaced and the pin tightened up. These are standard procedures on the steering racks we rebuild.

The torsion bars on the short tower racks came in four different sizes. The two smaller sizes were used on both the 6 and 12 cylinder cars. The early short tower racks had a torsion bar with a diameter of .190". These were used up until 1979 when a new rack design that used teflon seals on the main shaft was introduced. The newer rack used a torsion bar with a diameter of .210". This gave a really nice difference in the road feel and steering firmness. The 7 and 8 tooth pinions were also used in this rack until 1983, when the 7 tooth was dropped. In 1990 the "Sport" rack was introduced, using a .235" torsion bar. This rack was optional on the XJS with the Sport Pack but the rack can be installed in the earlier cars. The rack mounts were also improved, allowing less side-to-side movement. The ultimate pinion was in the XJRS rack, which used a .250" torsion bar. This is what is on my XJS and it really gives a wonderful road feel. They are very hard to come by these days as they did not make many XJRS cars.

Approximately in 1983, a new style of tie rod was introduced. The older style had the inner knuckles which used shims to adjust the clearance in the joint. The newer style used a nylon knuckle compressed around the round end of the tie rod. This gave virtually no free play and very smooth movement. This tie rod was used through the rest of the range until the ZF racks came into use. (This design is still being used on the new cars).

The easiest way to tell which tie rod you have is to see which size wrench it takes to unlock the tie rod end. The earlier style nuts used a 15/16" and the later a 7/8". The later ones also have a different thread on the ends so the tie rod ends are not interchangeable. There is also a 13mm flat spot on the later tie rods for alignment adjustment. This tie rod and tie rod end can be used on any of the earlier sedan or XJS racks, as it mounts the same and is the same length.

Regarding interchangeabilit, a lot of people have switched to the later short tower rack, replacing a tall tower rack. One big advantage is the faster ratio with the 8 tooth pinion and the firmer feel with a stiffer torsion bar. The rack will bolt-in just fine. The only things that need to be changed are the hoses and the lower steering column. The hoses can be made, modified, or ordered as parts for the Series 3 XJ6. The outlet valve on the power steering pump will need a later end, which is easily changeable on the car without removing the pump. The later hose uses a O-ring on the pump end instead of a metal flare fit on the high pressure line. The newer low pressure hose will bolt right in with no modifications.

The lower steering column will need to be replaced with the longer lower column from a later car, to join to the shorter rack tower. There are two versions of this piece. The early cars used nylon bushings in the swivel joint near the head of the rack. When Jaguar went to the short tower rack with catalytic converters, they continued to use the nylon bushings. Unfortunately the heat from the new catalytic converter melted the nylon bushings, causing excessive free play in the steering. Jaguar soon came out with an improved design using bronze bushings (and a rubber coupler to keep the power steering groan out of the steering wheel). This is the lower column that is used on all of the XJ6/3 cars and therefore are rather easy to source.

No matter which rack is used, pay close attention to the condition and type of rack mounting bushings. The stock mounts are fine if the side thrust washers are used and installed properly. The problem is that not too many shops know how to do this. The OE Jaguar Sport mounts are the best, as the washers are built in and they are still rubber isolated, but these are rather expensive and require special tools to install.

There are several types of aftermarket rack bushings available. In my experience, the softer aftermarket mounts made of rubber or neoprene get real mushy when exposed to oil and heat. The harder mounts, usually made from polyurethane, are easy to install and hold up well, though they may transmit a bit more road "noise" than the stock ones.

Please feel free to email me if anything here is not clear or if you have any questions.